sc 920 instruction manual

Welcome to the SC-920 Instruction Manual, your comprehensive guide to understanding and operating the SC-920 control box for direct-drive sewing machines. This manual provides essential information for setup, operation, and maintenance, ensuring optimal performance in industrial sewing applications.

1.1. Purpose and Scope

The SC-920 Instruction Manual is designed to provide a comprehensive guide for the installation, operation, and maintenance of the SC-920 control box. Its purpose is to ensure users can effectively utilize the device with direct-drive sewing machines, optimizing performance in industrial sewing applications. The manual is intended for operators, maintenance personnel, and technicians, offering detailed instructions for setup, troubleshooting, and routine maintenance. The scope of this manual covers all essential aspects of the SC-920, including hardware components, software configuration, and safety precautions. It serves as a reference for understanding the device’s capabilities, compatibility, and proper usage. By following this manual, users can ensure safe and efficient operation of the SC-920, maximizing productivity and extending the lifespan of the equipment.

System Requirements and Compatibility

The SC-920 is compatible with direct-drive sewing machines and supports remote control via a portable hand terminal. It works seamlessly with SC-921 models and vacuum pump systems, ensuring optimal performance in laboratory settings.

2.1. Compatible Sewing Machines and Devices

The SC-920 is designed for use with direct-drive (DD) sewing machine heads, enabling precise control and efficient operation. It is also compatible with the SC-921 model and can integrate with vacuum pump systems, enhancing functionality in various industrial applications. Additionally, the SC-920 supports remote operation through a portable hand terminal, providing flexibility in laboratory and production environments. This compatibility ensures seamless integration with existing machinery, making it a versatile choice for diverse sewing needs. Proper installation and setup, as outlined in the manual, are crucial for optimizing performance across all compatible devices.

Installation and Setup Guide

Welcome to the SC-920 Installation and Setup Guide. Carefully unpack the unit, and follow the step-by-step instructions for physical and software installation. Proper setup ensures optimal performance and functionality.

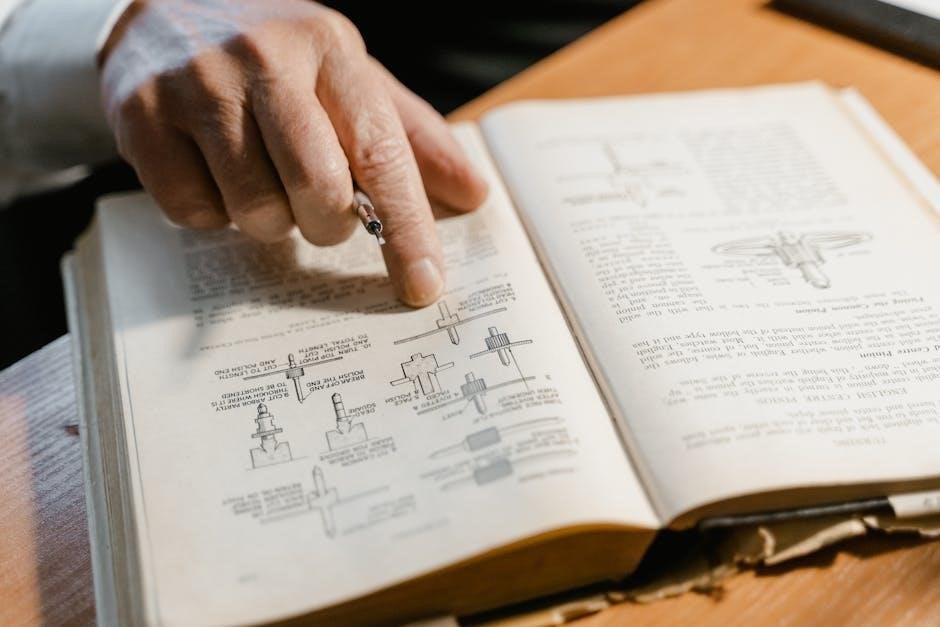

3.1. Unpacking and Physical Installation

Begin by carefully unpacking the SC-920 control box and its accessories. Ensure all components are included and undamaged. For physical installation, mount the control box securely on the table as per the manual’s instructions. If using the DD (direct-drive) sewing machine head, position the control box appropriately to ensure proper operation. Avoid exposing the unit to direct sunlight or moisture. Follow the provided diagrams for correct placement and alignment. Once installed, proceed to connect the necessary cables and power supply, ensuring all connections are secure. Refer to the manual for specific installation requirements for different machine configurations. Proper physical installation is crucial for the SC-920 to function efficiently and safely in your sewing setup.

3.2. Software Installation and Configuration

Install the SC-920 software from the official JUKI website or the provided installation media. Ensure the software version is compatible with your system. Run the installer and follow on-screen instructions to complete the installation. Once installed, connect the SC-920 control box to your computer via the appropriate interface. Open the software and select the correct COM port to establish communication; Configure settings such as stitch count, sewing speed, and other parameters according to your requirements. Refer to the manual for detailed configuration options. Restart the system after configuration to ensure all settings are applied. For troubleshooting, consult the manual or contact JUKI support. Proper software setup ensures seamless operation of the SC-920 with your sewing machine, optimizing performance and productivity.

Operating the SC-920

Operate the SC-920 by using the control panel to adjust settings, start/stop the machine, and monitor operations. Refer to the manual for detailed instructions on optimizing performance.

4.1. Controls and Functions Overview

The SC-920 control box features an intuitive interface designed for seamless operation. Key controls include speed adjustment, stitch selection, and emergency stop. The control panel also includes indicators for power status, error messages, and operational mode. Users can navigate through menus to customize settings such as stitch length, thread tension, and motor speed. Additional functions like reverse stitching and automatic thread cutting enhance efficiency. The SC-920 is compatible with direct-drive (DD) sewing machine heads, ensuring precise control. For advanced users, remote operation via a portable hand terminal is supported, enabling flexibility in industrial or laboratory settings. Always refer to the manual for detailed instructions on configuring and operating these features safely and effectively.

Safety Precautions and Guidelines

Ensure safe operation by following all safety guidelines in this manual. Avoid handling dangerous or flammable media without proper precautions. Always maintain a clean workspace and follow proper maintenance procedures to prevent accidents.

5.1. Handling the Device Safely

Always handle the SC-920 with care to ensure safe operation and longevity. Avoid exposing the device to extreme temperatures, moisture, or direct sunlight. When working with dangerous or flammable media, follow all safety protocols outlined in this manual. Keep loose clothing and long hair tied back to prevent accidents. Never attempt to modify the device or use unauthorized parts, as this may lead to malfunction or injury. Ensure the workspace is well-ventilated and free from dust. Regularly inspect cables and connections for damage. Use only approved cleaning materials to avoid damaging sensitive components. Read all safety guidelines before operating the SC-920, and ensure all personnel are properly trained. Always unplug the device before performing maintenance or repairs.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance and prevents downtime. Perform routine checks, clean components, and address issues promptly. Refer to the manual for detailed troubleshooting procedures and solutions.

6.1. Routine Maintenance Tasks

Regular maintenance is crucial for the smooth operation of the SC-920. Start by cleaning the control box and ensuring all connections are secure. Check for dust buildup in vents and internal components, as this can affect performance. Inspect and replace worn or damaged cables and connectors. Lubricate moving parts periodically to prevent friction and wear. Update software and firmware to the latest versions for optimal functionality. Refer to the manual for specific maintenance schedules and procedures tailored to your device. Addressing these tasks regularly will extend the lifespan of your SC-920 and ensure reliable operation in industrial sewing applications. Always follow safety guidelines during maintenance to avoid damage or injury.

Technical Specifications

The SC-920 is a discrete control box designed for use with direct-drive (DD) type sewing machine heads, offering compatibility with a range of industrial sewing applications. It supports compact motor units when properly configured, ensuring efficient operation. The system features remote control functionality via a portable hand terminal, enhancing flexibility in laboratory and industrial settings. The SC-920 is engineered to work seamlessly with high-speed sewing machines, providing precise control over stitching and zigzag functions. Its design includes advanced safety features and durable construction for long-term reliability. Technical details such as weight, dimensions, and power requirements are outlined in the manual, along with specific guidelines for installation and operation. This section provides a comprehensive overview of the device’s capabilities, ensuring users understand its technical capabilities and limitations.

Accessories and Parts

The SC-920 control box is compatible with a variety of accessories and parts designed to enhance its functionality and ensure optimal performance. Key accessories include the compact motor unit, which must be installed according to the manual’s instructions for proper operation. Additionally, the system supports remote control via a portable hand terminal, offering flexibility in industrial and laboratory settings. Essential parts such as connectors, cables, and control panels are detailed in the manual, along with guidelines for their installation and maintenance. For users requiring additional components, authorized Juki dealers provide genuine parts and accessories. This section outlines the available options, ensuring users can easily identify and procure necessary items to maintain or upgrade their SC-920 system effectively.

Warranty and Support Information

The SC-920 control box is backed by a comprehensive warranty program designed to ensure customer satisfaction and product reliability. For detailed warranty terms, including coverage duration and conditions, refer to the official Juki warranty documentation provided with your purchase. Additionally, Juki offers dedicated support services, including technical assistance, troubleshooting, and repair options. Users can access support through authorized Juki dealers or by contacting Juki’s customer service directly. The manual also provides guidance on how to register your product and utilize warranty services effectively. For any inquiries or issues, ensure to have your product serial number and purchase details readily available. This section emphasizes the importance of adhering to warranty conditions to maintain coverage and ensure uninterrupted operation of the SC-920 system.

Downloading the SC-920 Manual

To access the SC-920 instruction manual, visit the official Juki website or authorized dealer platforms. The manual is available for free download in multiple languages, including English and Spanish. Ensure to select the correct model, SC-920, from the product list. Additionally, third-party websites like ManualsLib and Manualzilla host the manual for convenient access. When downloading, verify the file format (PDF) and size to ensure completeness. For offline use, save the manual to your device or print it for easy reference. Always refer to the official sources to avoid outdated or incorrect versions. If you encounter issues, contact Juki support for assistance. This manual is essential for understanding the SC-920’s features, setup, and operation, so download it today to optimize your experience with the device.

Advanced Features and Settings

The SC-920 offers advanced features designed to enhance functionality and customization. One key feature is its remote control capability via a portable hand terminal, allowing for flexible operation in laboratory settings. Additionally, the SC-920 supports PC control software, enabling users to program and monitor settings from a computer. This feature is particularly useful for precise control and automation in industrial applications. The device also includes customizable settings for sewing parameters, such as stitch length and speed, which can be adjusted to suit specific tasks. Advanced diagnostics and real-time monitoring ensure optimal performance and quick troubleshooting. For specialized applications, the SC-920 integrates seamlessly with optional accessories, such as vacuum pump systems, to handle demanding materials. These advanced features make the SC-920 a versatile and powerful tool for professional sewing and industrial use, catering to a wide range of needs and environments.

The SC-920 instruction manual serves as an essential resource for optimizing the use of this advanced control box. Designed for compatibility with direct-drive sewing machines, the SC-920 offers a blend of versatility, precision, and ease of use. By following the guidelines outlined in this manual, users can unlock the full potential of the device, ensuring efficient operation in various industrial and laboratory settings. The manual’s detailed sections on installation, operation, and maintenance provide a comprehensive roadmap for both novice and experienced users. Whether you’re setting up the system, troubleshooting issues, or exploring advanced features, this guide equips you with the knowledge needed to maximize productivity. With its robust design and user-friendly interface, the SC-920 is a reliable tool for professionals seeking high-performance sewing solutions. Refer to the manual regularly to maintain optimal functionality and stay informed about updates or enhancements.