mapei aquadefense instructions

Mapei AquaDefense offers a swift and simple solution for waterproofing substrates‚ ensuring reliable protection before tile application. This premium system is designed for various areas.

It’s ideal for balconies‚ terraces‚ bathrooms‚ and shower cubicles‚ providing a robust barrier against water damage and enhancing the longevity of your tiling projects.

What is Mapei AquaDefense?

Mapei AquaDefense is a premium‚ flexible‚ crack-bridging waterproofing membrane‚ specifically engineered for use prior to the installation of ceramic‚ porcelain‚ and stone tiles. It’s a liquid-applied system‚ meaning it’s brushed or rolled onto surfaces‚ creating a seamless‚ waterproof barrier.

This product‚ often referred to as Mapelastic AquaDefense‚ excels in areas susceptible to water exposure‚ like balconies‚ terraces‚ and wet rooms. It’s designed to accommodate minor substrate movement‚ preventing cracks from compromising the waterproofing integrity. AquaDefense isn’t just a coating; it’s a comprehensive waterproofing solution‚ offering peace of mind and protecting your investment.

Key Features and Benefits

Mapei AquaDefense boasts exceptional crack-bridging capabilities‚ accommodating minor substrate movements and preventing water ingress through developing fissures. Its ease of application – simply brush or roll on – significantly reduces installation time and complexity. The product forms a seamless‚ waterproof membrane‚ eliminating potential weak points often found in multi-piece systems.

Furthermore‚ AquaDefense exhibits excellent adhesion to various substrates‚ ensuring a durable and long-lasting waterproofing layer. It’s compatible with a wide range of tile adhesives and offers superior protection against water damage‚ extending the life of your tiled surfaces. This translates to reduced maintenance and increased property value.

Preparation Before Application

Proper surface preparation is crucial for AquaDefense’s performance. Inspect for existing damage‚ thoroughly clean the substrate‚ and ensure it’s structurally sound before application begins.

Surface Preparation Requirements

Before applying Mapei AquaDefense‚ the substrate must meet specific requirements for optimal adhesion and waterproofing performance. Surfaces should be structurally sound‚ clean‚ dry‚ and free from dust‚ dirt‚ grease‚ oil‚ loose particles‚ and any other contaminants that could interfere with bonding.

Existing coatings‚ such as paint or previous waterproofing membranes‚ may need to be removed depending on their condition and compatibility. Concrete surfaces should be properly cured and free from cracks or significant imperfections.

Cement boards require taped seams and corners with a polymer-modified thin-set mortar before AquaDefense application. Always refer to the manufacturer’s guidelines for specific substrate recommendations.

Checking for Existing Damage

A thorough inspection for existing damage is crucial before applying Mapei AquaDefense. Carefully examine the substrate for cracks‚ voids‚ or any signs of structural instability. Existing cracks wider than approximately 1/8 inch (3 mm) should be repaired with a suitable patching compound‚ following the manufacturer’s instructions.

Pay close attention to corners and seams‚ as these are common areas for water penetration. Ensure that any previous repairs are sound and properly bonded to the substrate. Addressing these issues proactively will prevent future problems and ensure a durable‚ waterproof system.

Document any damage found before proceeding with surface preparation.

Cleaning the Surface

Proper surface cleaning is paramount for optimal Mapei AquaDefense adhesion. Begin by removing all loose debris‚ dust‚ dirt‚ and contaminants. A thorough sweeping or vacuuming is essential. Following this‚ wash the surface with a suitable cleaning solution‚ ensuring it’s compatible with the substrate and AquaDefense.

Rinse thoroughly with clean water to remove any cleaning residue. Allow the surface to dry completely before proceeding with application. Oil‚ grease‚ or any other bond-breaking substances must be completely eliminated. A clean‚ dry surface guarantees a strong‚ lasting waterproof barrier.

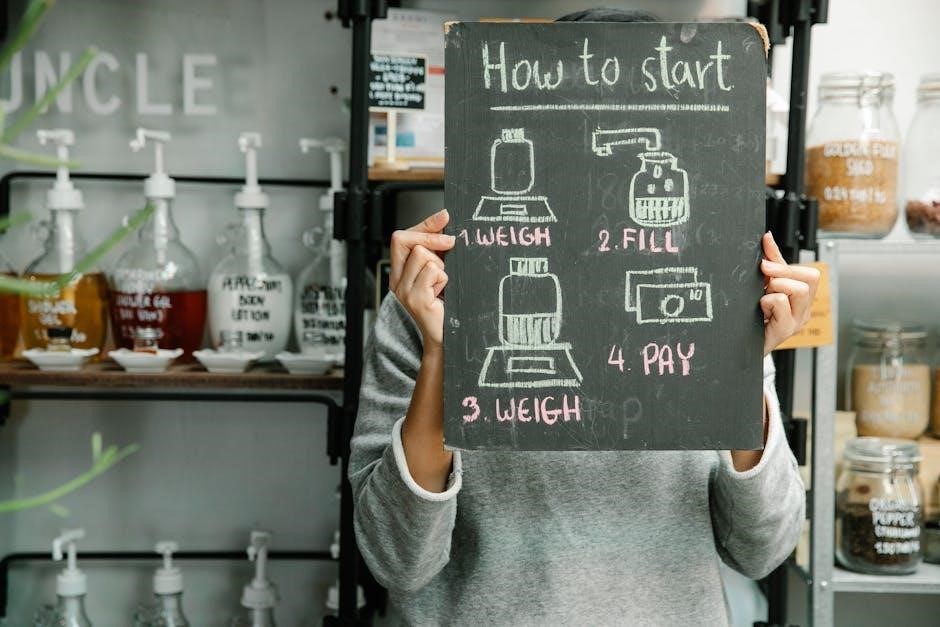

Application Instructions: Step-by-Step

Begin with mixing the AquaDefense compound thoroughly. Apply the first coat evenly‚ then reinforce with mesh tape at corners and seams. Finish with a second coat!

Mixing the Mapei AquaDefense Compound

Careful mixing is crucial for optimal performance. Begin with a clean bucket and slowly add the liquid component to the powder‚ while continuously mixing with a low-speed drill and paddle.

Avoid rapid mixing‚ which can introduce excessive air. Continue mixing until a smooth‚ consistent‚ and lump-free consistency is achieved. The mixture should resemble a creamy paste‚ easily spreadable but not overly runny.

Always refer to the product’s technical data sheet for the precise liquid-to-powder ratio‚ as this can vary. Properly mixed AquaDefense ensures excellent adhesion and waterproofing capabilities‚ setting the foundation for a successful application.

Applying the First Coat

Begin application using a notched trowel‚ holding it at a 45-degree angle to ensure consistent coverage. Apply the Mapei AquaDefense in smooth‚ even strokes‚ working in manageable sections. This initial coat serves as the primary bonding layer‚ penetrating the substrate for a strong connection.

Ensure complete coverage‚ paying close attention to corners and edges. The first coat doesn’t need to be excessively thick‚ but it must be uniform. Allow this coat to dry thoroughly‚ following the manufacturer’s recommended drying time before proceeding to the next step.

Reinforcing with Mesh Tape

After the first coat has sufficiently dried‚ apply self-adhesive mesh tape to all corners‚ seams‚ and any potential crack zones. Ensure the tape is firmly embedded into the still-tacky surface of the AquaDefense. Overlap the tape slightly at the edges for a continuous‚ reinforced barrier.

This mesh tape is crucial for preventing cracking and ensuring long-term waterproofing integrity. Apply Mapelastic AquaDefense liquid 6 (15 cm) on both sides of the cracks‚ fully encapsulating the mesh. This step significantly enhances the system’s ability to withstand movement and stress.

Applying the Second Coat

Once the first coat‚ including the mesh-taped areas‚ is fully dry‚ proceed with the application of the second coat of Mapei AquaDefense. This coat provides complete coverage and reinforces the waterproofing membrane. Apply evenly‚ ensuring all areas are thoroughly coated‚ paying close attention to corners and seams.

The second coat builds upon the foundation laid by the first‚ creating a robust and reliable barrier against water penetration. Allow sufficient drying time between coats‚ as per the manufacturer’s instructions‚ before proceeding to the next stage of your tiling project.

Specific Application Areas

Mapei AquaDefense excels in waterproofing balconies‚ terraces‚ bathrooms‚ and shower cubicles before applying ceramic‚ stone‚ or mosaic coatings‚ offering superior protection.

Balconies and Terraces

Applying Mapei AquaDefense to balconies and terraces requires meticulous surface preparation to ensure long-lasting waterproofing. Begin by thoroughly cleaning the substrate‚ removing any debris‚ dirt‚ or existing coatings. Address any cracks or damage with appropriate repair materials before application.

Apply the first coat of AquaDefense evenly‚ ensuring complete coverage. Reinforce corners and seams with mesh tape‚ embedding it within the wet compound. Follow with a second coat‚ overlapping the tape for a seamless‚ waterproof membrane.

Pay close attention to drainage areas‚ pre-treating drains according to manufacturer guidelines to maintain effective water runoff and prevent potential issues.

Bathrooms and Shower Cubicles

Mapei AquaDefense is exceptionally well-suited for waterproofing bathrooms and shower cubicles‚ creating a reliable barrier against moisture penetration. Prioritize thorough surface preparation‚ ensuring the substrate is clean‚ dry‚ and free of contaminants. Address any existing cracks or imperfections before commencing application.

Apply the first coat of AquaDefense uniformly‚ paying close attention to corners and areas around plumbing fixtures. Embed mesh tape in these critical zones‚ followed by a second coat to fully encapsulate the tape and create a watertight seal.

Proper drain pre-treatment is crucial; adhere to the drain manufacturer’s specific instructions for membrane installation.

Areas Prone to Water Exposure

Mapei AquaDefense excels in safeguarding areas frequently exposed to water‚ like balconies‚ terraces‚ and around windowsills. Begin with meticulous surface preparation – cleaning‚ drying‚ and repairing any existing damage are paramount. Ensure compatibility with the substrate before application.

Apply the first coat evenly‚ focusing on potential weak points and areas where water might accumulate. Reinforce corners and seams with mesh tape‚ embedding it fully within the AquaDefense compound.

Follow with a second coat for complete coverage and a robust‚ waterproof membrane. Remember to consult drain manufacturer guidelines for proper pre-treatment and sealing.

Working with Corners and Seams

Proper taping techniques are crucial; fully embed mesh tape with AquaDefense‚ applying it to both sides of corners and seams for optimal waterproofing.

Proper Taping Techniques

Effective corner and seam treatment is paramount for a successful Mapei AquaDefense application. Begin by ensuring all corners are clean‚ dry‚ and free of debris. Apply the mesh tape‚ carefully embedding it into the corner using firm‚ even pressure.

Crucially‚ extend the tape at least 6 inches (15 cm) onto the adjacent surfaces on both sides of the corner or seam. This overlap provides a robust bonding area.

Avoid wrinkles or air pockets beneath the tape‚ as these can compromise the waterproofing integrity. After the tape is firmly in place‚ proceed with applying the AquaDefense compound directly over the taped areas‚ ensuring complete saturation and a smooth‚ even coat.

Applying AquaDefense to Taped Areas

Following proper taping‚ generously apply Mapei AquaDefense over the embedded mesh tape. Utilize a notched trowel to ensure consistent thickness and optimal coverage. Work the compound firmly into the tape‚ completely saturating it to create a seamless‚ waterproof bond.

Pay close attention to fully encapsulate the tape edges‚ preventing any exposed areas. Apply with smooth‚ overlapping strokes‚ avoiding air entrapment. A second coat over the taped areas is essential for enhanced durability and complete waterproofing.

Ensure the second coat fully covers the first‚ creating a uniform layer. Allow adequate drying time between coats‚ as per the manufacturer’s instructions.

Drainage and Waterproofing

Pre-treat drains before application and carefully review the drain manufacturer’s specific instructions for membrane installation alongside Mapei AquaDefense for optimal results.

Pre-treating Drains

Prior to applying Mapei AquaDefense‚ meticulous drain pre-treatment is crucial for a watertight system. Begin by ensuring the drain area is clean and free of debris.

Apply a generous coat of AquaDefense around the drain flange‚ extending approximately 6 inches (15 cm) beyond the perimeter. This creates a secure seal.

Reinforce this area with mesh tape‚ embedding it fully within the AquaDefense layer. Pay close attention to the corners and edges of the drain for complete coverage.

Allow this initial coat to dry before proceeding with the overall waterproofing application‚ ensuring a robust and reliable connection between the drain and the membrane.

Following Drain Manufacturer Instructions

Crucially‚ always consult and adhere to the specific installation guidelines provided by the drain manufacturer. These instructions often detail unique requirements for waterproofing membrane integration.

Mapei AquaDefense is designed to work in conjunction with‚ not as a replacement for‚ proper drain installation procedures. Some manufacturers may specify particular primers or bonding agents.

Pay close attention to recommendations regarding membrane overlap onto the drain flange and any specific sealing compounds required. Ignoring these details can compromise the waterproofing integrity.

Prioritize the drain manufacturer’s guidance to ensure a fully compliant and leak-proof installation‚ maximizing the effectiveness of the AquaDefense system.

Safety Instructions

Always prioritize safety by utilizing appropriate Personal Protective Equipment (PPE) and ensuring adequate ventilation during preparation and application of Mapei AquaDefense.

Personal Protective Equipment (PPE)

When working with Mapei AquaDefense‚ comprehensive personal protective equipment is crucial for safeguarding your health. Always wear chemical-resistant gloves to prevent skin contact with the compound‚ as prolonged exposure can cause irritation. Safety glasses or goggles are essential to shield your eyes from splashes and potential fumes.

A dust mask or respirator is highly recommended‚ especially during mixing and application‚ to avoid inhaling any airborne particles. Protective clothing‚ such as a long-sleeved shirt and pants‚ will minimize skin exposure. Ensure all PPE is in good condition and fits properly for maximum effectiveness. Prioritize your well-being by adhering to these safety guidelines throughout the entire process.

Ventilation Requirements

Adequate ventilation is paramount when applying Mapei AquaDefense to ensure a safe and healthy working environment. Work in a well-ventilated area‚ preferably with open windows and doors‚ to facilitate airflow and dissipate any potential fumes released during application.

If working indoors with limited natural ventilation‚ utilize fans to circulate air and consider a mechanical ventilation system. This is particularly important in enclosed spaces like bathrooms or small rooms. Proper ventilation minimizes the risk of inhaling vapors and maintains acceptable air quality. Always consult the product’s safety data sheet for specific ventilation recommendations.

First Aid Measures

In case of skin contact with Mapei AquaDefense‚ immediately wash the affected area thoroughly with soap and water. For eye contact‚ flush with copious amounts of water for at least 15 minutes‚ lifting upper and lower eyelids occasionally.

If irritation persists‚ seek medical attention. If inhaled‚ move to fresh air. If breathing is difficult‚ administer oxygen and consult a physician. Should ingestion occur‚ do not induce vomiting; immediately contact a poison control center or medical professional. Always have the product’s safety data sheet readily available for medical personnel.

Drying Time and Curing

Allow sufficient drying time between coats‚ as recommended by Mapei. Full curing is essential before tile installation to ensure optimal waterproofing performance and adhesion.

Recommended Drying Time Between Coats

Following the application of the first coat of Mapei AquaDefense‚ allowing adequate drying time is crucial for optimal performance. Generally‚ a drying period of approximately 2 to 4 hours is recommended before applying the subsequent coat.

However‚ this timeframe can be influenced by environmental factors such as temperature and humidity. Higher temperatures and lower humidity levels will typically accelerate the drying process‚ while cooler temperatures and increased humidity may necessitate a longer drying time.

Always refer to the product data sheet and installation guide for specific recommendations tailored to your project conditions. Ensuring proper drying between coats promotes strong interlayer adhesion and prevents potential issues like blistering or delamination.

Full Curing Time Before Tile Installation

Before commencing tile installation over the Mapei AquaDefense waterproof membrane‚ allowing for complete curing is paramount. A minimum curing time of 72 hours‚ or three full days‚ is generally recommended under normal conditions of temperature and humidity.

This allows the AquaDefense compound to reach its full strength and develop optimal adhesion to the substrate. Premature tile installation can compromise the waterproofing integrity and lead to potential failures down the line.

Always consult the product data sheet for specific curing times based on environmental conditions. Verify the membrane is fully dry and firm to the touch before proceeding with tile work.

Troubleshooting Common Issues

Addressing imperfections like bubbles or cracking requires immediate attention. Ensure proper surface preparation and application techniques to avoid these issues during the waterproofing process.

Dealing with Bubbles or Imperfections

Bubbles or imperfections appearing within the Mapei AquaDefense application can often be rectified. Immediately address small bubbles by gently smoothing them out with a clean‚ notched trowel while the compound is still wet.

For larger imperfections‚ allow the first coat to fully dry before carefully scraping away the flawed area. Re-apply AquaDefense to the corrected spot‚ ensuring proper coverage and eliminating air entrapment.

Consistent‚ even application is key to preventing these issues. Avoid rapid application and ensure the trowel is held at the correct angle for optimal spreading and adhesion. Thorough surface preparation also minimizes potential problems.

Addressing Cracking

Cracking in the Mapei AquaDefense membrane typically indicates underlying movement or insufficient reinforcement. Small hairline cracks may be acceptable if they remain flexible with substrate movement. However‚ larger cracks require immediate attention.

Reinforce the affected area with additional mesh tape‚ extending well beyond the crack’s perimeter. Apply a generous coat of AquaDefense over the reinforced area‚ ensuring complete saturation of the tape.

Address the source of the movement if possible. If the cracking persists‚ consult a structural engineer to evaluate the substrate’s stability before proceeding with tile installation. Proper preparation is crucial for long-term performance.

Post-Application Considerations

Protect the waterproofed surface from damage during construction. Regular maintenance will extend the membrane’s lifespan‚ ensuring lasting protection against water intrusion and structural issues.

Protecting the Waterproofed Surface

After applying Mapei AquaDefense‚ safeguarding the newly waterproofed area is crucial before proceeding with tile installation. Avoid heavy foot traffic directly on the membrane‚ as it can cause punctures or indentations. Cover the surface with protective materials like cardboard or plywood sheets to prevent damage from tools‚ dropped objects‚ or construction debris.

Pay particular attention to corners and edges‚ as these are more susceptible to accidental impacts. If any damage occurs‚ immediately repair it with additional AquaDefense compound and mesh tape to maintain a continuous‚ watertight seal. Proper protection ensures the integrity of the waterproofing system and prevents costly repairs later on.

Maintenance and Longevity

To maximize the lifespan of your Mapei AquaDefense waterproofing system‚ routine inspections are recommended‚ particularly in areas prone to significant water exposure. Check for any signs of cracking‚ blistering‚ or delamination of the tile or membrane. Address any issues promptly to prevent water infiltration and potential structural damage.

Avoid using harsh chemicals or abrasive cleaners that could compromise the membrane’s integrity. Regular cleaning with mild detergents and water is sufficient. With proper installation and consistent maintenance‚ Mapei AquaDefense provides long-lasting‚ reliable waterproofing protection‚ ensuring the durability and value of your tiled surfaces for years to come.